Achieving energy efficient operation while preventing liquid from damaging your compressors is a key consideration when designing refrigeration systems. The ideal requirement is to achieve the optimal balance between protecting your compressors and getting maximum refrigeration capacity from your evaporator. Danfoss has pioneered two control algorithms that help you achieve this balance.

The Minimum Stable Superheat (MSS) algorithm has been an important part of the Danfoss ADAP-KOOL® offering for years and is still the ideal choice for adaptive evaporator control for dry expansion. Now Danfoss introduces the next generation: Adaptive Liquid Control (ALC).

广泛的安全利润可以降低系统性能

Many retail refrigeration systems are designed to run with high fixed superheat as a safety measure to avoid damage to the compressors. This is an understandable precaution, as refrigeration system failure is costly, leading to downtime and customer inconvenience. However, setting too wide a safety margin for superheating results in poor system performance and high energy consumption. The evaporators are not utilized fully, and this results in less efficient refrigeration and increased energy consumption. Adaptive evaporator control, by contrast, optimizes system performance and energy consumption. Danfoss offers two different adaptive control algorithms, but before we look at them in detail, let us briefly recap what happens in the evaporator.

What happens in the evaporator?

液体制冷剂被注入蒸发剂中,在该蒸发器中蒸发,从而在过程中吸收了来自环境的热量。最初,大多数制冷剂仍处于其液态状态,但是随着蒸发的发展,气体(蒸气)与液体比率增加。气体比液体占用更多的空间,增加了制冷剂的速度,其余的液体滴在气体中旋转。如果对制冷剂的注射速率得到了充分的控制,则所有液体在到达蒸发剂末端之前已经蒸发,仅留下过热气体。

为了更好地理解不同的控制策略,让我们看一下蒸发器内部。如果我们想象蒸发器是一根长管,从左侧注入制冷剂(见图1),制冷剂从一开始就开始沸腾。如果仍然存在液态形式的制冷剂(直到干燥点),则可以将超热测量为零。在蒸发器的一部分中,液滴和制冷剂气体混合物(称为雾流面积),气体的温度非常不稳定。一旦所有液体液滴蒸发,并且仅存在气体,温度信号再次变得稳定,气体的温度升高。通过测量蒸发剂入口(通常是转化为温度的蒸发压力)和在蒸发器出口处测量的温度之间的制冷剂温度之间的差异,可以控制注射的制冷剂的量。该温度差通常表示为过热。

由于雾气流域中制冷剂气体的温度信号非常不稳定且难以控制,因此通常通过设置固定(稳定的)过热参考来控制注射,以确保只有制冷剂气体离开蒸发剂,从而保护该蒸发剂压缩机针对液体滑动。

固定过热控制

通常,通过设置通常6至12开尔文的固定引用来控制超热。在现实世界应用中,超热设置取决于蒸发器的类型以及负载和运行条件,这意味着与部分负载条件相比,在高负载条件下需要更高的超热参考。为了保护压缩机,针对最坏情况的情况设置了高固定的过热参考,结果蒸发器效率在部分负载条件下较差。

Minimum Stable Superheat control

不稳定和稳定的超热信号之间的边界处的温度称为最小稳定信号或最小稳定超热(MSS)。这是所有制冷剂变为气相的点,这是获得最佳效率和稳健操作之间最佳权衡的点。从这一点开始,由于制冷剂处于气相,因此不再存在对压缩机损坏的风险。为了优化制冷系统性能,必须仔细控制制冷剂注射,以使蒸发器尽可能多地填充,而不会有任何液体返回压缩机的风险。最佳超热有助于最佳性能

对于系统和最高的蒸发器容量。因此,控制注射阀以保持最佳的过热是设计,安装和操作制冷系统的关键考虑。如果操作条件总是相同的,那么定义最佳超热将不是一个重大挑战。但是,在现实世界中,不同类型的蒸发器,操作条件和负载变化导致最佳超热的变化。这意味着您不能依靠固定的过热设置,因为您要么在蒸发器利用率不佳或由于液体效果而损坏压缩机的风险。为了确保最佳操作并保护您的系统,应使用自适应控制方法。

The Minimum Stable Superheat algorithm: a proven technology invented by Danfoss

最小稳定的超热(MSS)算法是Danfoss的Adap-Kool®产品的一部分,并于1987年引入。进行了优化以处理制冷剂注射,它仍然是自适应蒸发器控制干燥膨胀的最有效方法。MSS算法在所有负载条件下控制注射阀,使系统能够以低热量至3 kelvin的高温操作,并不断适应条件变化。使用MSS,蒸发器表面的利用率最大化,同时确保没有液体退出蒸发剂。MSS算法与吸力压力优化结合使用可提供最大的系统效率。当启动冷藏系统时,MSS算法从参考设定点减少了超热,直到通过控制制冷剂注射来测量信号中的不稳定性(见图2)。然后逐渐增加过热的参考,直到信号再次变得稳定,然后再次降低,直到不稳定性再次出现。该过程是连续执行的,并根据实际负载条件和蒸发器动态调整控制参数。MSS提供了一些好处。不管负载如何,白天/夜晚的环境温度变化,使用夜幕及季节性差异,MSS始终确保最低的能耗和稳定的病例温度,通常导致与非适应性相比,能源节省10%或更多控制方法,例如固定的超热设定点或具有机械恒温膨胀阀的系统。 MSS ensures that all liquid has evaporated before reaching the end of the evaporator. This allows the system to optimize the suction pressure to the highest possible level while keeping even a fully loaded supermarket display case at the desired temperature. In summary, significant energy savings can be realized through the use of adaptive superheat control of evaporators. Across the world, thousands of retailers use the MSS algorithm in their refrigeration

从节能和最佳食品安全中受益的系统。

How to obtain the highest evaporator efficiency

当可以不断控制干燥点以正确地位于蒸发器的末端,以确保蒸发器的主要部分的环形流动时,蒸发器的最高效率就会实现。不幸的是,在干燥的扩展系统中,这是不可能的,因为制冷剂的液滴会离开蒸发器,最终到达压缩机,并导致压缩机损坏的高风险。如果系统的设计使压缩机不暴露于液体,例如使用吸气蓄能器和泵工作将过量的制冷剂带回接收器,最好的策略是控制制冷剂的干燥点,尽可能接近蒸发器的末端。如果液体仅通过蒸发剂淹没,最终进入吸气蓄能器,则不会增加蒸发剂的能力。相反,这只会导致额外的能量用于循环大量的液体。同样,将需要更大的蓄能器来保护压缩机免受液体裂缝的侵害。

Adaptive Liquid Control (ALC): controlling superheat as close to zero as possible Despite its age, the MSS algorithm is still exceptional in terms of precision, stability, reliability, and efficiency. Danfoss, however, has now developed its adaptive evaporator control offering even further, introducing the Adaptive Liquid Control (ALC) algorithm that allows even better evaporator utilization with highly precise liquid control. With the ALC algorithm, you can take refrigeration system performance to the next level.

冷藏中的超热是什么?

在冷藏中,超热(SH)是高于饱和温度(沸点)的制冷剂气体与其饱和温度之间的温度差。对于每个开尔文都可以减少过热,增加蒸发温度的潜力相等。对于每个开尔文,蒸发温度都会提高,可以将2-3%的能量保存在制冷系统中。

较高的吸力压力降低了压缩机能耗

MSS算法的基石之一是,它通过确保没有液体退出蒸发剂来保护压缩机。使用干膨胀蒸发器时,这是最佳解决方案。但是,对于具有吸气蓄能器的系统,在不要求没有液滴离开蒸发器的情况下,可以进一步增强蒸发器的利用,减少超热并实现最佳能源效率。通常用于跨批评CO的ALC算法2systems with Liquid Ejectors injects greater amounts of refrigerant into the evaporator, fully utilizing the entire surface. Increasing the amount of refrigerant increases the evaporation temperature, bringing the superheat very close to zero. As stated above, every degree Kelvin of increase in evaporation temperature makes it possible to save 2-3% energy in a refrigeration system. With ALC, the refrigerant leaving the evaporator has not been superheated.

The suction pressure is, therefore, higher, reducing the load on the compressors. With an increase in evaporation temperature of up to 5 Kelvin compared to adaptive MSS systems, and even more when compared to non-adaptive solutions, significant energy savings can be achieved. The trade-off is that the refrigerant leaving the evaporator is part liquid. The Danfoss ALC algorithm, however, is capable of controlling the evaporation process very precisely, keeping the amount of liquid low. This means that the suction accumulator installed to collect these droplets of liquid can be small, lowering the first cost and saving installation space. By adding a Danfoss Liquid Ejector, you can drain away the liquid from the suction accumulator without consuming additional energy. For more information on the Danfoss ejector offering, see our article The Danfoss ejector range for CO2制冷:设计,申请和福利或访问Multiejector.danfoss.com

Four different control strategies for refrigerant injection in evaporators

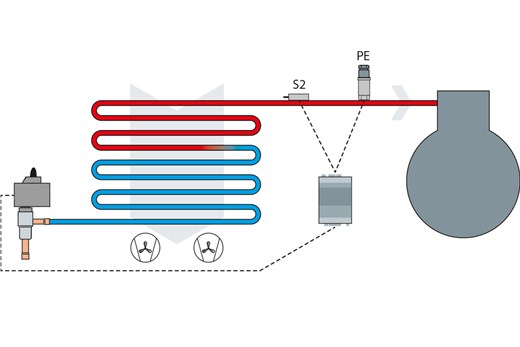

1. Fixed superheat control

为了确保不损害压缩机的强大控制

conditions are required, compromising full utilization of evaporator capacity.

固定过热控制in dry expansion systems. Typically seen in competitor systems and systems

带有恒温膨胀阀。与MSS相比,能源消耗增加。

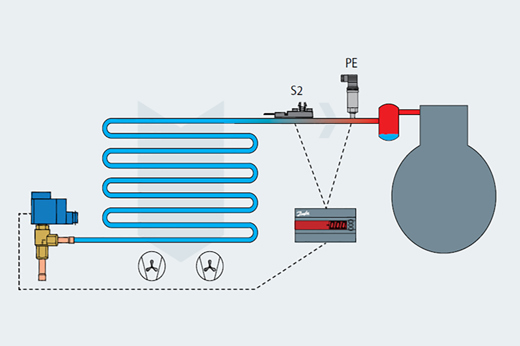

2. Danfoss adaptive MSS control

使用MSS,可以最大程度地利用蒸发器表面,同时确保没有液体退出蒸发剂。MSS算法与吸力压力优化结合使用,可在干燥膨胀的系统中最大程度地效率。自引入以来,经过验证的Danfoss MSS控制驾驶超过150万个AKV阀。与固定的过热控制相比,提供多达10%的节能。

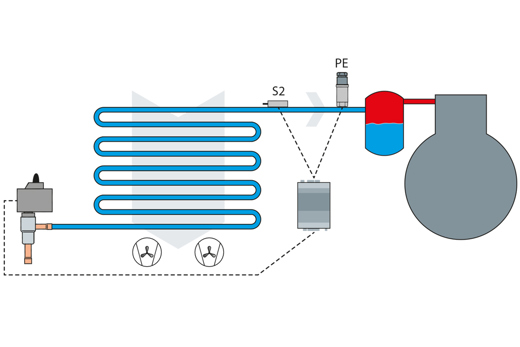

3. Danfoss Adaptive Liquid Control (ALC)

通常用于跨批评CO的ALC算法2带有吸气蓄能器和液体喷射器的系统在蒸发器中注入更多的制冷剂,充分利用整个表面。增加制冷剂的量会增加蒸发温度,使超热非常接近零。新的Danfoss ALC算法提供了最高的

utilization of evaporator capacity, enabling up to 5 Kelvin higher suction pressure compared to MS control and even twice as much compared to systems with fixed superheat.

4. Flooded evaporator control

在接近零的固定超热设置的竞争对手系统中可以看到洪水泛滥的蒸发器控制。当测量超热为零时,无法控制流速。因此,需要在洪水和干燥膨胀之间切换适当的机制。在蒸发器控制泛滥的竞争对手系统中,需要更大的吸力蓄能器来遏制多余的液体并保护压缩机,而蒸发器中未看到额外的容量增加。

ALC:the best control strategy for CO2systems with the suction accumulator and ejectors By controlling the superheat close to zero and fully utilizing the evaporator, you get optimum evaporation effect from the refrigerant. This allows you to minimize the amount of liquid circulated in the system. This Danfoss solution for managing liquid in transcritical CO2仅由于案例控制,包装控制和系统管理器的增强版本以及液体喷射器,制冷应用只能进行。该解决方案称为CO2自适应液体管理(平静),这代表了制冷剂管理方面的重要一步。自适应系统的大脑是自学习控制器。有关跨批评CO中使用的Danfoss AK-PC和AK-CC控制器的更多信息2系统,请参阅我们的文章智能和适应性控制。2refrigeration.

Conclusion

在过去的几十年中,来自数千个安装的数据证明了自适应超热控制的优势。在CO中有几种实现最佳超热的方法2制冷系统 - 您选择的蒸发器控制策略取决于许多因素。Danfoss提供了自适应,智能和验证的控制方法,可提供运营储蓄和高系统可靠性。经过验证的MSS算法是自适应蒸发器控制干燥膨胀的最佳选择,而在吸气线中不需要液体中的液体。新的ALC算法是具有吸气蓄能器和液体喷射器的系统的最佳选择,使您可以选择最佳地利用蒸发器。无论您选择哪种解决方案,与固定的过热系统相比,可以实现大量的节能。有关更多信息,请联系您当地的Danfoss销售办公室或访问smartstore.danfoss.com